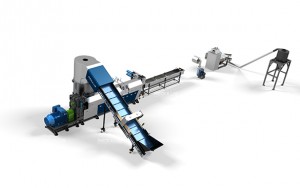

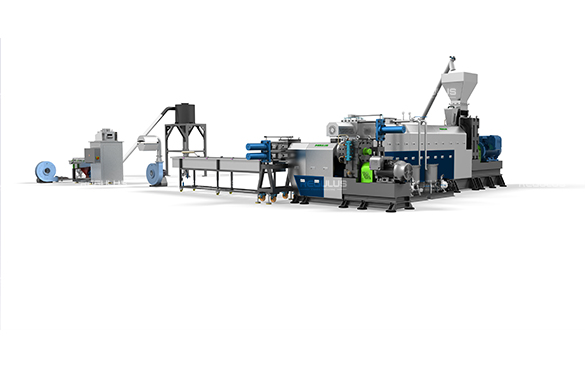

Hal marxalad kareem cutter compact-ka dib-u-warshadaynta xariiqda dhaleeceynta

Faahfaahinta

| Ujeedada loo bartilmaameedsaday | Hdpe, LDPE, PP, PP, CPP, OPP, PC, PC, PC, PU, PUN | |||||

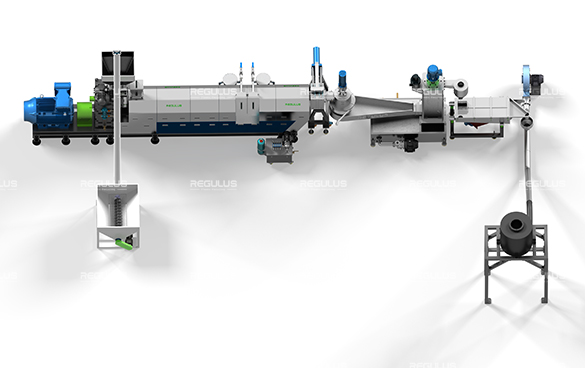

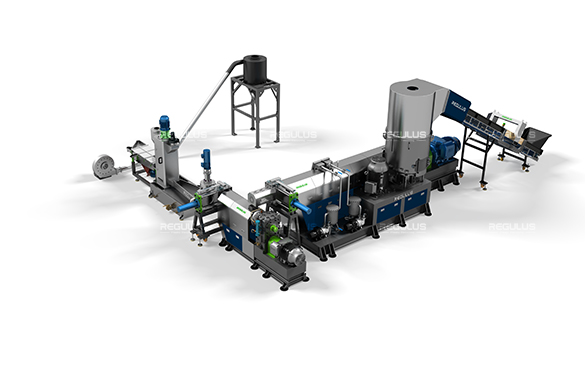

| Nidaam ka kooban | Suunka suunka, goynta compant, hal mar ah oo lagu daboolo, xaddiga,Pelletizer, Qalabka qaboojinta biyaha, qaybta fuuqbaxa, fan funnimada, silo wax soo saarka. | |||||

| Qalabka xoqan | 38croala (sacm-645), bimetal (ikhtiyaari) | |||||

| L / d oo lagu daboolo | 28/1, 30/1, 33/1, (iyadoo loo eegayo astaamaha dib-u-warshadaynta) | |||||

| Kuleyl foosto | Kuleyliyaha kuleylka ee dhoobada ah ama kuleylka fog | |||||

| Qaboojinta foosto | Qaboojinta hawada ee marawaxadaha iyada oo loo marayo fariisiyaasha | |||||

| Nooca dharkaaga | Biyo-Biyo-dhaji / biyo-biyo-mareennada / biyo-galka ku qoran | |||||

| Adeegyada Farsamada | Naqshadeynta Mashruuca, Dhismaha Warshadda, Rakibaadda iyo Talooyinka, Komishanka | |||||

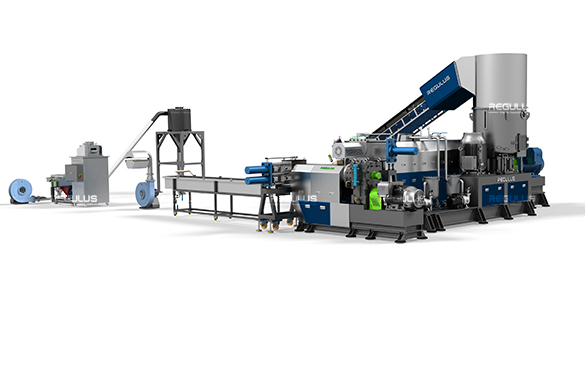

| Noocee | Qalab isbarbar ka kicin | L / d | Hal mar | |||

| Mug | Awood koronto | Dhexroor furan | Majirto garka | Awoodda wax soo saarka | ||

| (Litir) | (kW) | (mm) | (kW) | (kg / saacad) | ||

| Xy-85 | 350 | 37 | 85 | 33 | 55 | 150-250 |

| Xy-100 | 500 | 55 | 100 | 33 | 90 | 250-350 |

| Xy-130 | 850 | 90 | 130 | 33 | 132 | 450-550 |

| Xy-160 | 1100 | 110-132 | 160 | 33 | 185 | 650-800 |

| Xy-180 | 1500 | 185 | 180 | 33 | 250-280 | 900-1100 |

Qalabka qashinka lagu daro ee lagu daro nidaamka qashinka lagu qoro

Nidaamka taxanaha ah iyo nidaamka dhakhaatiirta ayaa isku daraya howsha burburka, isqaba, la-qabsashada, hufan iyo qufaca hal talaabo. Lagu dabaqay balaastikada passyclngng iyo habka loo yaqaan 'peletizing'. Nidaamka ACSH TM waa xalka lagu kalsoonaan karo oo hufnaan leh oo loogu talagalay filimka balaastigga, Raffias, xaashiyaha, boorsooyinka, boorsooyinka la tolay iyo alaabada xumaha ah ee dib u soo celinta mashiinka waxqabadka sare. Waxay bixin kartaa wax soo saar sare laakiin leh tamar hoose oo tamar ah. Codsiga: PE, PP, PP, Abs, XPS, EPS, PVB.

Quuditaanka

Sida naqshadeynta caadiga ah, xoqida balaastigga ah sida filimka, dabada, Raffiasku wuxuu gaadhsiiyay qolka isqaba ee loo marayo suunka. Si wax looga qabto 'xoqida' Freesps ', duubista aaladda ka soo baxa waa hab quudinta ikhtiyaariga ah. Gawaarida wata ee suumanka loo yaqaan 'conveyor suunt' iyo aaladda goynta ayaa iska kaashadaya injirta. Xawaaraha quudinta ee suunka kombiyuutarka ama duubista ayaa si buuxda si buuxda u otomaatig ah iyadoo lagu saleynayo sida ay u buuxiso qolka compuptuctu.

Burburin iyo is-miidaaminta

CODTACT waxaa ku qalabeysan aaladda daalay hawada. Iyada oo ay la socoto shaqada farsamada mindi mindi iyo mindida mindida hoose ee korka sare, heerkulka kombuyuutarka iyo walxaha ayaa si tartiib tartiib ah u kordhin doona ka dib goynta iyo kala-baxa, iyo ciidda dusha sare ee sheyga ceyriinka ah. Qalabka ayaa si wax ku ool ah uga saari kara qoyaanka iyo boodhka, kaas oo ka fogaan doona isticmaalka isticmaalka tamarta dheeriga ah si uu ula macaamilo qoyaanka.habka quudinta.

Burburka wareegga ee kombiyuutarka

Guryaha wareegga iyo faashad go'an ayaa u jaray sheyga digaaga yar. Xannibaadda kuleylka ah ee ay ka dhashaan xargaha xawaaraha sare ee xawaaraha sare waxay kululaan doonaan oo burburin doonaan jajabka.

Hal mar

Naqshadeena gaarka ah ee loo yaqaan 'Blacts' oo si tartiib ah loo soo saaro oo si tartiib ah u balaqaabiyo oo isqarxin karo qalabka. Biyaha noolaha ah ee birta leh waxay leedahay iska caabin ka hortagga badan, xidho waqti u adkeysan oo cimri dheer.

DIIWAAN GALINTA DHAQANKA

Iyada oo labanlaab labanlaab ah aagaga, deganaanshuhu, sida molole-molecules iyo qoyaan ayaa laga saari doonaa hufnaan si loo wanaajiyo tayada granuluse, gaar ahaan ku habboon qalabka culus ee daabacan.

Nooca shaashadda shaashadda shaashadda

Filterka nooca saxanka ah waxaa lagu sameeyaa nooc joogto ah oo leh laba taarikada shaandhada. Ugu yaraan hal filter ayaa shaqeynaya marka shaashadu is beddeleyso.

Midkoodna ha joojinin shaandhada Nooca Piston

1.A oo caadi ah / taarikh labaad oo laba-laablaab ah oo shaashadda ah ama bastooladaha laba-joogsiga ah ee shaashadda / bastooladaha '' Saldhigga 'Saldhigga Afarta' waxaa lagu rakibi karaa madaxa soo-saarista si loo soo bandhigo waxqabadka muhiimka ah.

2.Long Shaashada nolosha, isbedelka shaashadda hoose: Lihil dheer oo Lihil ah oo loogu talagalay meelaha miiraha waaweyn ee waaweyn.

3. Way fududahay in la isticmaalo iyo nooca aan joogsi lahayn: isbadal fudud oo qeexan oo looma baahna in la joojiyo mashiinka socda.

4. Qiimaha hawlgalka hoose ee hoose.

Xargaha caaryada

Caaryada jiidaha ayaa si ballaaran loo istcimaalaa, iyo alaabta ceyriinka ah sida pp, pe, ab, xayawaan, iwm. Waxaa lagu dabaqi karaa dhaqaale ahaan iyo dhaqaale ahaan

Caymiska caagga ah ee caaga ah

1. Fursad dheeri ah oo kacsan oo kudhaca ah oo lagu daro isku-dhafka-nooca-centrifugal-ka ee centrifugal-ga ee centrifugal-ga oo soo bandhigaya waxqabadka sare ee qalalan

2. Isku soo wada ururinta Searchs: Shuruudaha waxaa lagu rakibay oo lagu hagaajiyaa boolal halkii ay ka gaari lahaayeen alxamida, sidaa darteed waxaad u beddeli kartaa daruuraha si fudud mustaqbalka.

Calaaladaha caaga ah ee caaga ah ee qaboojinta

Loo adeegsaday ka saarida qoyaanka geeska balaastigga ah

Nidaamka goynta khadadka caagga ah ee caaga ah

Loo adeegsaday goynta xargaha caaga ah ee walxaha

shaashadda gariirka

Loo isticmaalaa in lagu kala saaro cabirka ka kooban walxaha balaastigga ah